|

|

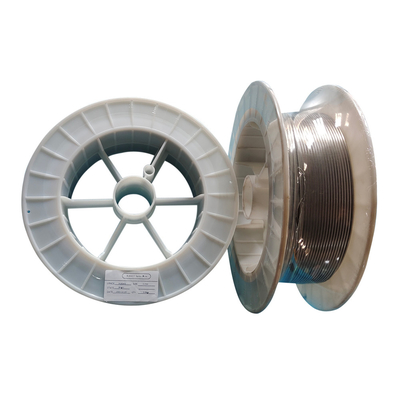

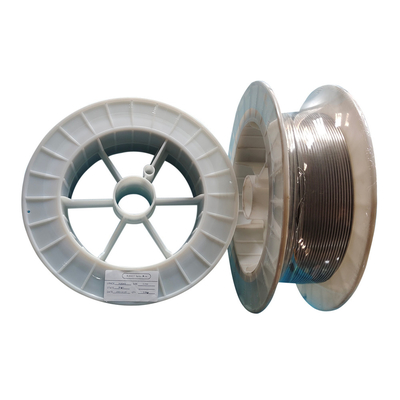

Hastelloy C276 TIG MIG Welding Wire, AWS A5.14 ERNiCrMo-4, UNS 2.4819, for Corrosion Resistance

|

|

उत्पाद विवरण:

भुगतान & नौवहन नियमों:

|

विस्तृत उत्पाद विवरण

| सामग्री: | हास्टेलॉय सी-276 | व्यास: | 1.6 मिमी, 2.0 मिमी |

|---|---|---|---|

| पैकेट: | 15 किग्रा / स्पूल | आवेदन: | थर्मल स्प्रे कोटिंग |

| छिड़काव का तरीका: | चाप छिड़काव | बांड शक्ति: | 10000 साई |

| जमा दक्षता: | 70% | ||

| प्रमुखता देना: | Hastelloy C276 welding wire,ERNiCrMo-4 TIG MIG wire,corrosion resistant thermal spray wire |

||

Hastelloy C276 TIG MIG Welding Wire, AWS A5.14 ERNiCrMo-4, UNS 2.4819, for Corrosion Resistance

| Product | Chemical Composition | Available Sizes | Comparable Products | Hardness and Bond Strength | Typical Characteristics and Applications |

| Name | |||||

| Inconel 625 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 71T | 92 Rb | Caustic stress corrosion |

| Molybdenum | Metco 8625 | 6970 PSI | Restoration of worn or mismachined components | ||

| Ni 22Cr 10Mo 2Fe | |||||

| Inconel® 625 | |||||

| C-276 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 77T | 35 Rc | Acidic and hot gas corrosion |

| Molybdenum | 6990 PSI | Good abrasion and metal-to- metal wear | |||

| Ni 20Cr 20Mo 7Fe 4W | |||||

| Hastelloy C-276 | |||||

| Inconel 718 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 78T | 30 Rc | Acidic and hot gas corrosion |

| Molybdenum | Metco 8718 | 8992 PSI | Restoration of worn or mismachined components | ||

| Ni 18.5Cr 18.5Fe 3.0Mo | |||||

| Inconel® 718 | |||||

| SS 316 | Stainless Steel | 1.6mm, 2.0mm | Tafa 85T | 93-97 Rb | Corrosion protection |

| 316 S.S. | Metco Metcoloy 4 | 4100 PSI | Dimensional restoration | ||

| OCr25Al5 | Iron Chrome | 1.6mm, 2.0mm | Tafa 24CA | 88 Rb | Boiler applications |

| Aluminum | Praxair ALCRO | 7770 PSI | Excellent machinability | ||

| Fe 23.5Cr 5.3Al .65Si | Ability to have featheredge coatings |

![]()

![]()

FAQ

सम्पर्क करने का विवरण

Ohmalloy Material Co.,Ltd

व्यक्ति से संपर्क करें: Mr. Qiu

दूरभाष: +8613795230939

हम करने के लिए सीधे अपनी जांच भेजें

अधिक थर्मल स्प्रे तार